Quality Inspection & Traceability

DFARS and domestic material certifications

Full material traceability from the mill to our shop

CMM inspection reports

AS9102 First Article Inspection (FAI) reports

Certificates of conformance

Finishing certifications

Hardware certifications and traceability

ANY MATERIAL

Aluminum: 6061, 7075, MIC-6

Stainless Steel: 300 & 400 series, 17-4PH

Carbon Steels: C1018, C1144, C4140

Tool Steels: O1, A2, D2, H13

Copper Alloys: 110 Copper, 360 Brass, 954 Bronze

Titanium: 6Al-4V, 5AI-2.5V

Plastics: Delrin, ABS, Polycarbonate, UHMW

Composites: G10 Garolite, Fiberglass, Carbon Fiber

PART FINISHING

Bead blasting

Brushing and sanding

Etching

Teflon and PTFE coatings

Heat Treatment

Mechanical tumbling

Engraving

Anodizing – Type II and III with or without coloring

Chem-film / Alodine® / chromate conversion coatings

Painting and powder coating with masking

Passivation

Plating – Gold, Silver, Copper, Nickel, Tin, and Zinc

Electropolishing

Laser marking

MECHANICAL ASSEMBLY

Complete system assembly

Custom tooling assembly

Selection, torqueing, thread-locking, and tamper-proofing of fasteners

Press-fitting bearings, bushings, dowel pins, etc.

Installation of specialty hardware like Heli-coils®, Keenserts®, Lee plugs®, etc.

Sourcing & procurement of COTS components

UMC 500SS

FULL 5 AXIS MAX PART SWING 18”

X Axis 24.0 in

Y Axis 16.0 in

Z Axis 16.0 in

Max Spindle Speed 12000 rpm

Weight 12000lb

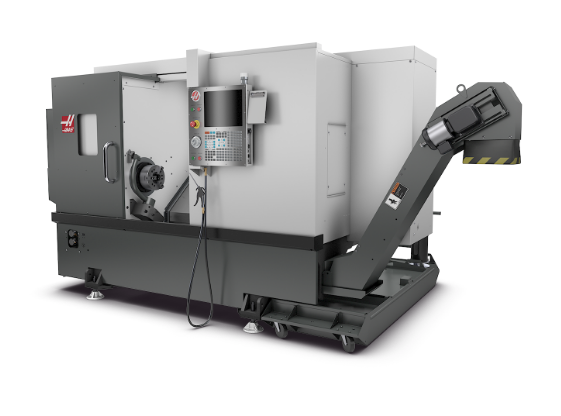

ST-25

Axis Travels (X, Z) 8.4″, 22.5″

Maximum Spindle Speed 3400-rpm

Weight 9000 lb

VF-2

X Axis 30.0 in

Y Axis 16.0 in

Z Axis 20.0 in

Max Spindle Speed 8100 rpm

Weight 7800 lb